Improving Visibility Across Operations

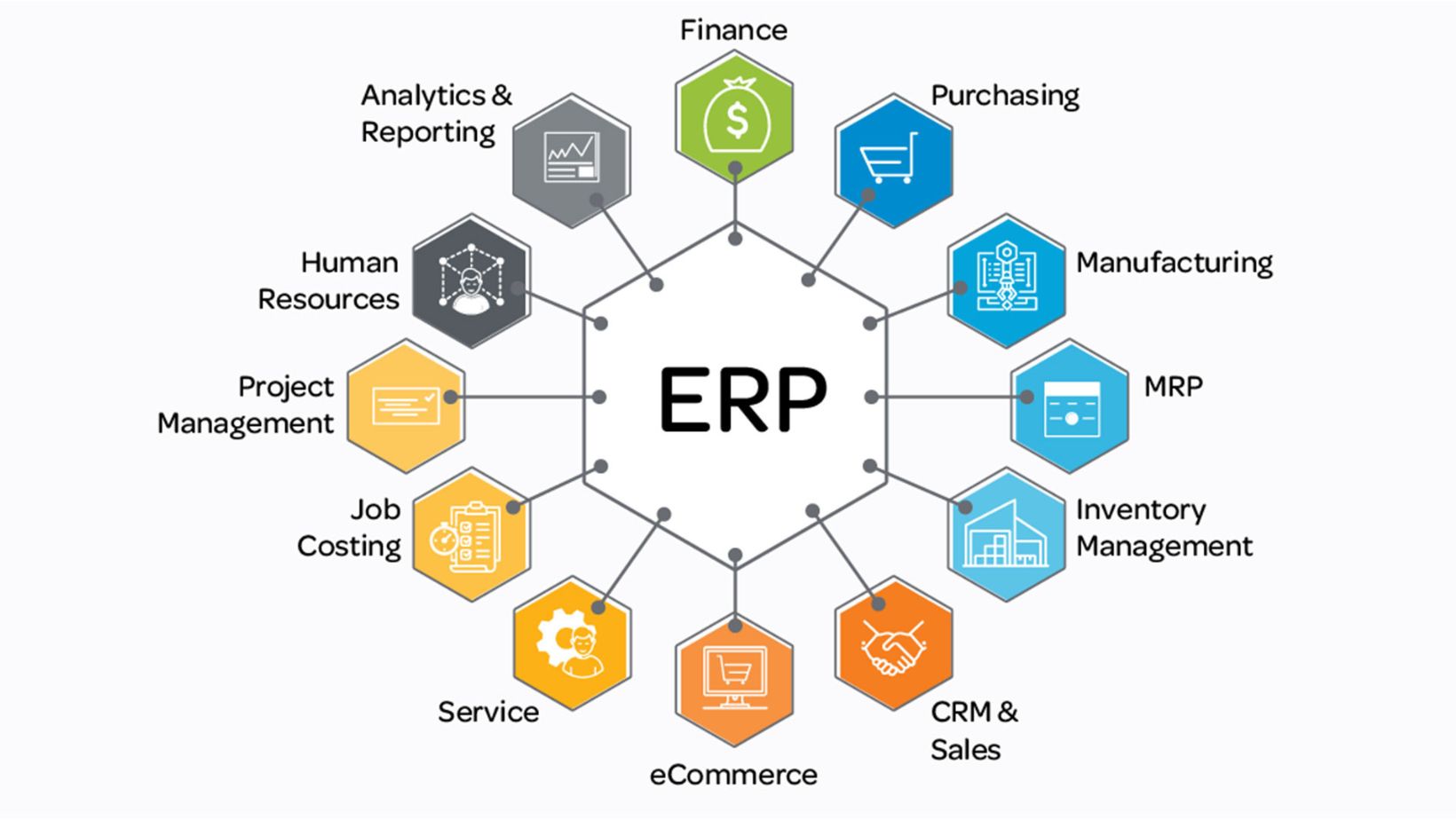

Enhancing lead time reduction requires organizations to monitor all production process elements. Business data collection of sales and procurement and inventory and shop floor operations happens through centralization on ERP systems. The single operational view through manufacturing ERP lets producers detect problems before they expand by spotting process delays and inefficiencies or bottlenecks.

Organizations that utilize real-time data access allow their teams to work without the need to wait for information updates or produce manual reports. The improved visibility system enables planning to transition from reactive to proactive decision-making. The new system allows manufacturers to handle changes in their environment faster because they no longer need to wait for delivery times to lengthen between order placement and product shipment.

Streamlining Procurement and Inventory Management

Waiting periods in procurement tend to become frequent reasons for prolonged delivery times. ERP systems execute automated purchase order generation that employs demand forecasting together with current stock status thus eliminating input delays and inventory outages. The system guarantees material availability by letting users define reorder points together with safety stock levels.

Tighter inventory control results from manufacturing ERP software because the system enables better tracking and planning capabilities. What’s in stock and its spatial location alongside upcoming job requirements allows manufacturers to prevent both over-stock and insufficient stock levels. Such control measures decrease the periods during which production operations stand inactive.

Enhancing Production Scheduling

The scheduling efficiency of production directly affects the reduction of lead times. Managers using ERP systems achieve workload optimization alongside decreased equipment breakdowns while maintaining capacity to match customer needs. ERP tools eliminate scheduling uncertainties that trigger delays by automatically streamlining the scheduling activities.

The manufacturing ERP system gives notifications about schedule adjustments in case machines have issues or orders need sudden changes. Through this functionality manufacturers maintain manufacturing flow while prioritizing emergency orders which might otherwise interrupt production operations. The production timeline shortens while maintaining consistent workflow because of such processes.

Integrating Sales and Operations Planning

The necessary cooperation between sales representatives and production staff helps to shorten delivery times. ERP systems unify business departments through their capacity to connect demand intake with production capacity. Teams responsible for sales gain better delivery expectations through their access to current production scheduling data and inventory visibility.

Company operations become more efficient when manufacturing plans incorporate customer orders because this system removes issues that stem from traditional coordination through human contact. Through manufacturing ERP software organizations achieve better forecasting that aids teams to prepare for sudden changes in demand while avoiding crisis situations. The exact match between manufacturing operations enables maintenance of short and reliable lead times.

Monitoring and Improving Performance Over Time

The continuous improvement of lead times is achievable through the use of your ERP system to track important performance indicators. Manufacturers can achieve better decision-making through performance tracking of order-to-delivery times and machine utilization rates and supplier outcomes metrics.

ERP dashboards together with reporting tools help decision-makers acquire necessary insights to optimize procedures and change resource distribution and vendor networks according to their needs. Long-term use of data-driven management leads to permanent decreases in lead duration coupled with improved operational efficiency.