You know well that every dollar saved is a dollar you can reinvest in the growth of your business. But what about the hidden costs lurking in your fluid transfer systems? Outdated equipment, inefficient processes, and unexpected downtime can drain your profits. That’s where smart technologies come in.

By leveraging the power of data, automation, and predictive analytics, you can optimize your operations, reduce waste, and achieve significant cost savings. Here are smart innovations in fluid transfer that can help you boost your bottom line.

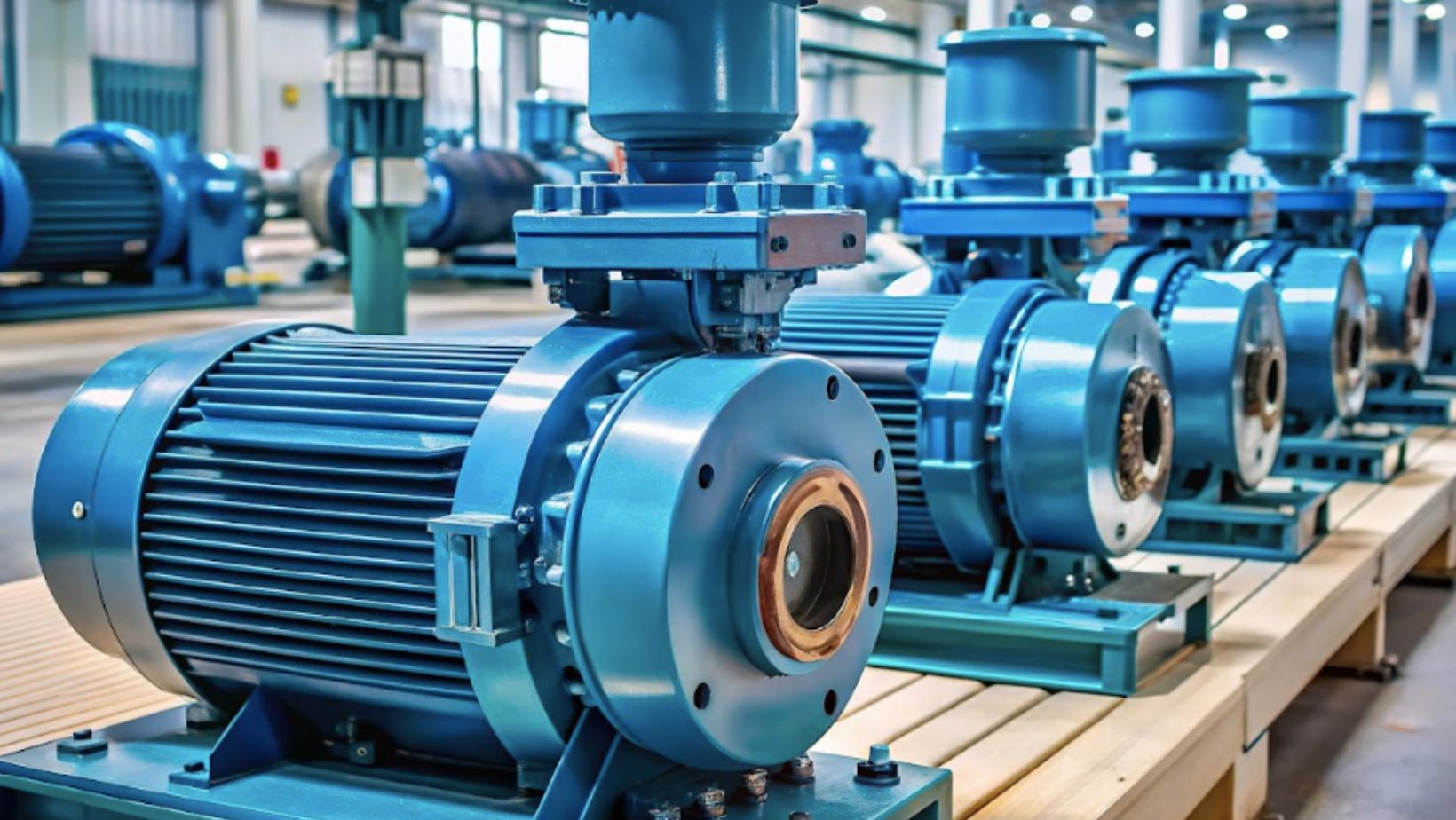

Advanced Pump Systems

Let’s start with the workhorse of any fluid transfer system: the pump. Traditional pumps are often energy-hungry and prone to breakdowns. But modern, advanced pump systems are a different story.

For example, diaphragm pumps manufactured by reputable companies like KNF, among others, provide precise and versatile transfer. Plus, these modern pumps are digitally customizable, making them energy-efficient. Given its low maintenance needs and durability, you’ll surely be able to cut operational costs.

Another exciting development in this field is the use of variable frequency drives (VFDs). These smart devices adjust the speed of the pump motor based on the actual demand, which can scale up and down according to the needs of the operation.

Many now come with predictive maintenance features, too. These systems use sensors and artificial intelligence to spot potential problems before they become major issues. This proactive approach can dramatically reduce unexpected downtime, saving both time and money.

Lastly, smart controls are making pump operations more hands-off than ever before. These systems can automatically adjust to changing conditions, ensuring optimal performance without constant human intervention.

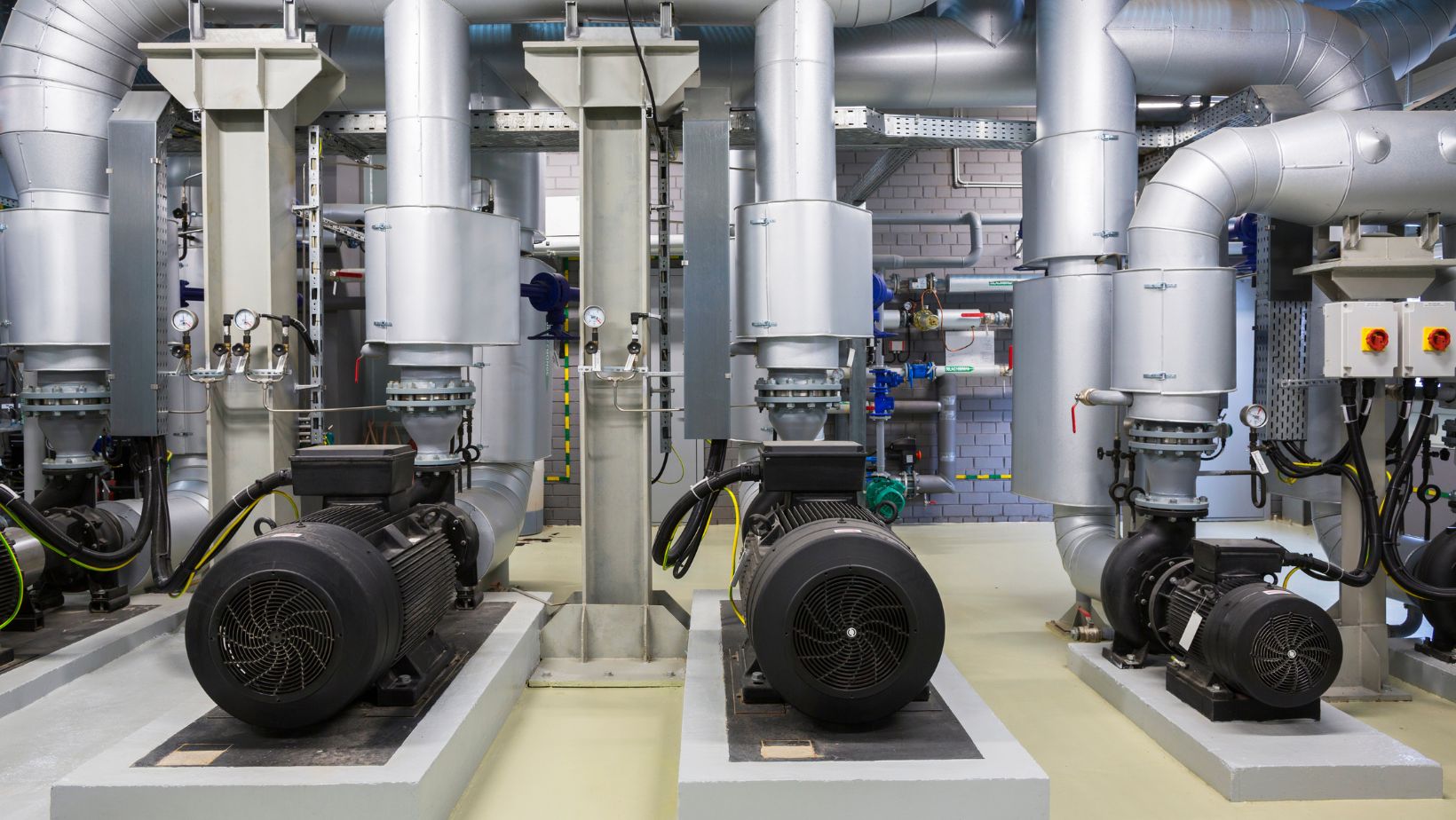

Improved Piping and Valve Design

Of course, pumps are only part of the story. The pipes and valves that carry the fluid are equally important. Here, too, smart technologies are making a big difference.

One of the most powerful tools in this area is computational fluid dynamics (CFD). This fancy term simply means using computers to simulate and optimize fluid flow. By creating virtual models of piping systems, engineers can spot potential problems and inefficiencies before a single piece of real pipe is laid. This can lead to designs that minimize energy loss and reduce the risk of costly failures.

Materials science is also playing a role in improving piping systems. New self-cleaning and corrosion-resistant materials are extending the life of pipes and reducing maintenance needs.

Smart valves are another game-changer. These high-tech marvels can precisely control flow rates, pressure, and other parameters. Some can even adjust themselves automatically based on changing conditions. This level of control can significantly reduce waste and improve overall system efficiency.

Monitoring and Analytics

Aside from their mechanical benefits, these technologies give you unprecedented insight into your system’s performance.

Real-time flow sensors and leak detection systems act like vigilant sentinels, constantly watching for any signs of trouble. They can spot even tiny leaks or variations in flow that might otherwise go unnoticed. This not only prevents waste but can also help avoid potentially dangerous situations.

But collecting data is only half the battle. The real magic happens when you apply advanced analytics to this information. Modern software can sift through mountains of data to identify patterns and inefficiencies that human observers might miss.

Many of these systems also offer remote monitoring and control capabilities. This means you can keep an eye on your fluid transfer operations from anywhere in the world and even make adjustments on the fly.

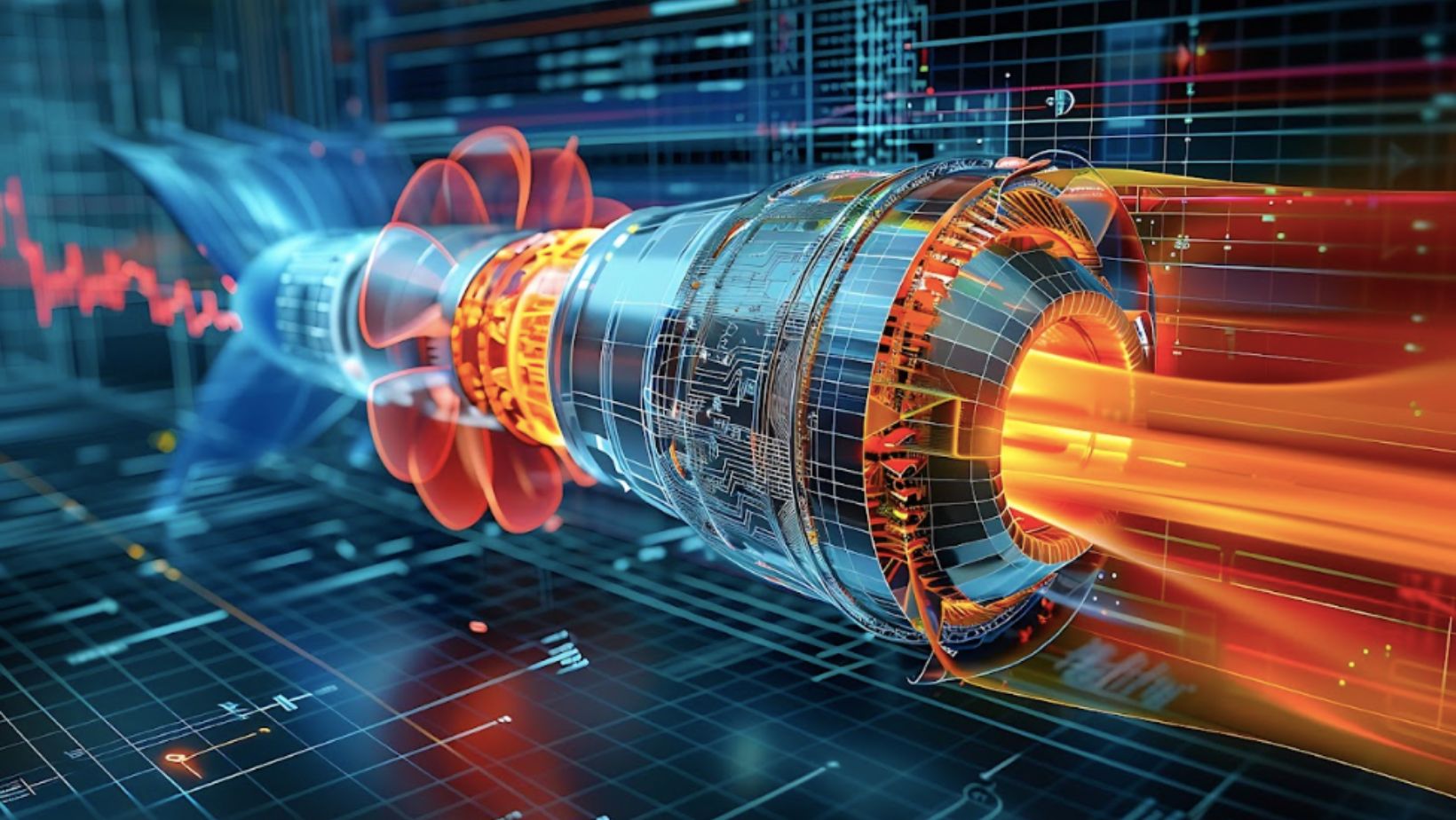

Process Optimization

With all this data and control at your fingertips, you can start thinking about optimizing the entire process, not just individual components. This is where things get really exciting.

Artificial intelligence and machine learning algorithms can analyze historical data and current conditions to optimize transfer schedules. This might mean running certain operations at night when energy costs are lower or coordinating multiple systems to work together more efficiently.

These smart systems don’t exist in isolation, either. They can be integrated with broader industrial Internet of Things (IoT) systems, allowing for even greater coordination and efficiency across your entire operation.

One of the most powerful tools in this area is the concept of digital twins. These are virtual replicas of your physical systems that allow you to test changes and optimizations in a risk-free environment.

Alternative Transfer Methods

Sometimes, the smartest solution is to rethink the problem entirely. That’s where alternative transfer methods come in.

For example, gravity-fed systems can be incredibly efficient in the right situations. By carefully designing your facility’s layout, you might be able to let gravity do some of the work for you, reducing the need for energy-hungry pumps.

For certain materials, pneumatic conveying systems that use air to move substances through pipes can be more efficient than traditional liquid-based systems.

There’s even research being done on hydraulic capsule pipelines, which use water to move solid capsules through pipes. This could potentially revolutionize how we transport certain goods over long distances.

Final Thoughts

As you’ve seen, there’s no shortage of innovative technologies aimed at making fluid transfer more efficient and cost-effective. From smarter pumps and pipes to advanced analytics and entirely new transfer methods, the future of fluid transfer looks bright indeed. By embracing these technologies, businesses can not only save money but also improve their environmental footprint and overall operational efficiency. It’s a win-win situation that’s hard to ignore.